International Cars

Industrial furnaces are used globally for a wide range of applications. As the selection of applications grew, different types of furnaces were developed to keep up with demands. This blog post will look at a selection of industrial furnaces and their applications.

Ashing Furnaces

Ashing furnaces are used to determine the amount of ash that forms after a sample is burned. Typical materials used as samples in ashing furnaces are petroleum products, lubricating oils, and coal.

This process is often used to determine any contaminants in the sample, which is sometimes only present if ash is produced. Ashing is used as a preconcentration method to determine any trace substances before chemical analysis.

Calcination Furnaces

Calcination furnaces are generally used to prepare raw materials for raw processing or to recover the base material following other processes.

Calcination is a heat treatment processes where samples including minerals or ceramic powders are heated below the melting point to induce phase transition, thermal decomposition, or to remove a volatile fraction.

Tempering Furnaces

Tempering furnaces are often used after iron-based alloys have been subjected to hardening or quenching, which can cause excess hardness, stress, and brittleness.

Tempering is the process of heating steel to a specific temperature and then cooling it in still air. The temperature the metal is heated to determines how much hardness is removed.

Annealing Furnaces

Annealing is a heat treatment process that is used to soften a sample for improved cold working, machinability, and to enhance mechanical and electrical properties.

Annealing furnaces work by heating up a material and maintaining the temperature before cooling at a suitable rate. Depending on the requirements, different temperatures and cooling rates will be used.

Sintering Furnaces

Sintering furnaces are used to reduce the porosity of a material and to enhance a specific property including strength, translucency, thermal conductivity, or electrical conductivity.

The sintering process works by forming and compacting a solid mass of material using pressure or heat without melting the sample to the point of liquefaction.

Tensile Testing Furnaces

Tensile testing furnaces are used to measure the ultimate tensile strength, yield strength, strain-hardening, and a range of other properties of a material.

These furnaces work by subjecting the sample to controlled tension until complete failure, and this is a popular test method for quality control.

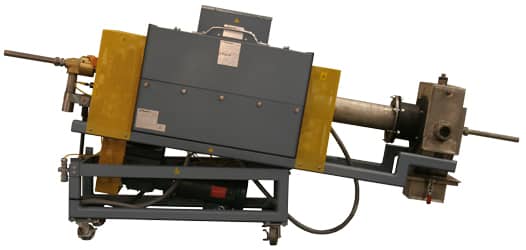

Rotary Tube Furnaces

Rotary tube furnaces are circular furnaces that rotate during heat treatment and are often used for continuous materials processing as they can apply heat in multiple thermal control zones.

Industrial Furnaces from Thermcraft

Thermcraft is global manufacturers of standard and custom industrial furnaces. Our products range from standard quick-ship designs to solutions that are fully customized to our customers’ needs.